- Computer Interface panel for acquire, analyze, and control.

- Labview/Matlab Software Compatiable.

- 4 Analog Input Channels with Output Control Channel.

- Embedded FPGA Control with an option of Graphical Module helps you develop HMI/SCADA or high-channel-count data-logging applications.

- Use this module to develop a distributed monitoring and control system with tags ranging from a few dozen to tens of thousands. It includes tools for logging data to a networked historical database, tracking real-time and historical trends, managing alarms and events, and adding security to user interfaces.

- Supports signal conditioning for RTD for Temperature, flow sensor (water) with F to V converter to generate 0-2.5Vdc (FS).

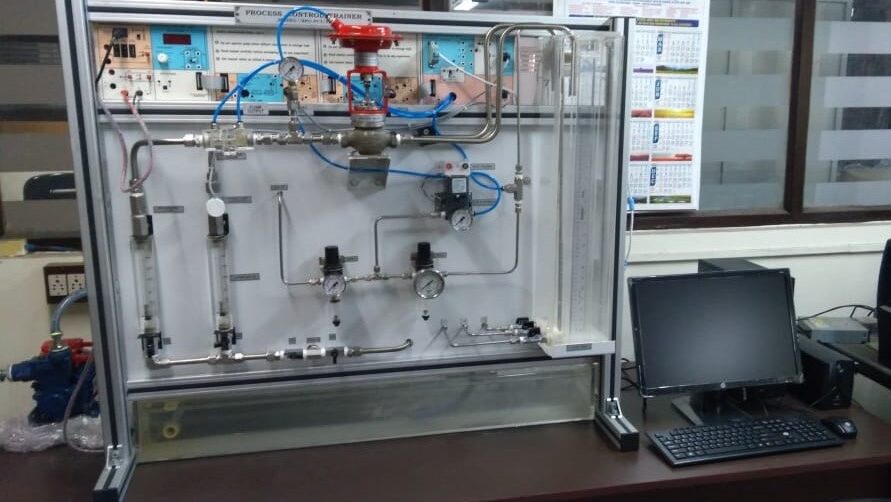

- Storage tank material/Capacity: 1 No., 10 litre plexiglass tank for water

- Process tank capacity/material: 1 No. 5 liter, stainless steel tank with temp,

- Temp: PT100, O/P =0 to 2.5V, ambient to 1000C

- Flow: Turbine flow sensor 1No. OP=0to2.5V, 0-150LPM

- Control Valve: Pneumatically operated air to close, linear type, ½ ” Size Diaphragm operated, C=0.4 with I to P Converter I/P 4 to 20mA O/P 4 to20 mA O/P 3 to 15 psi.

- TAP panel: SCR controlled full-bridge (200Vdc)for 750 for temp. control I/P 0 to 2.5Vdc.

- Rotameter: 2 Nos. Acrylic body ½ ” size 0 to 50LPM

- Generation & Distribution Pump: 230VAC 10W submersible water pump with ¼” PVC pipe to fill in process vessel for temp. control expt.

- Bourdon gauges: 2 Nos. 0 to 2 bars, 2Nos 0 to 10 bar 0-1000C gauge thermometer

- Modular panels for easy site servicing not close control.

- Lightweight, yet sturdy, tabletop, Aluminium profile flat panel setup, with SS (304/316) piping for and a wide-angle view of every component in the process.

- V to I and I to V function block: I/P 0 to 2.5V & O/P 0-20 or 4-20mA (100W load) switch settable.

- Individual control loops as well as Advance control schemes like Ratio, Cascade, Feedforward, coupled tank.

- Connection through polarized FRC connectors, sturdy 4mm Banana sockets & Patch cords enabling quick setting up of a variety of process control experiments.

- Software package with P, PI & PID control, Ratio & cascade control, three operating modes, Online graph drawing & data acquisition modes (SCADA).

- Multi-channel DPM for digital display of process parameters

- Thyristor Actuator cum signal conditioning panel

- Thyristor bridge based 0-200V/3A using cosine firing circuit, I/P 0 to 2.5Vdc.

- With Compatible Workstation to the above system, 64 Bit, Intel i5, 8 GB, 1 TB Hard disks, Monitor, Keyboard, and Mouse with genuine OS

CONTROL SYSTEM & MEASUREMENT

Process control trainer for water Flow and Level

For Pricing and other details contact us at sales@adlabts.com

| Weight | 45 kg |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.